Download information:

What is an Fluidized Bed Incinerator? (6,873.52 KB) What is an Fluidized Bed Incinerator? (6,873.52 KB)

|

What is a Fluidized Bed Incinerator?

What is a Fluidized Bed Incinerator?

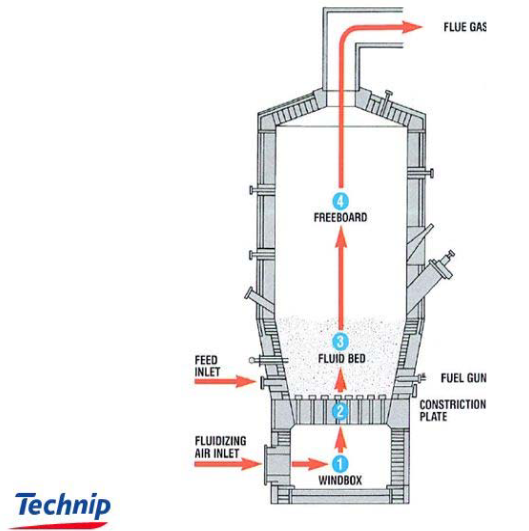

A Fluidized Bed Incinerator uses a bed of hot sand or other granular material to transfer heat directly to waste. It is commonly used for destroying municipal sludge.

Construction of a Fluidized Bed Incinerator

- Sizing based on heat balance air and gas volumes

- Auxiliary fuel choice (typically oil, gas, or dual fuel)

- Overbed air option for highly volatile wastes

- Improves reactor temperature profile

- Improves efficiency in turndown conditions

- Usually results in smaller dome diameter

- Generally not required for hot windbox municipal sludge incinerators (overbed air is not preheated)

Fluidized Bed Incinerator Heat Recovery

- Typical for municipal applications

- Minimal auxiliary fuel requirements

- Refractory dome distributor

- Developed by Dorr-Oliver in the 1950s

- Low risk design up to 22’ diameter dome

- Air preheater is a proven low-risk design

- Typical preheated air temperatures to 1200°F (air preheat to over 1400°F is possible when required)

Material Movement in a Fluidized Bed Incinerator:

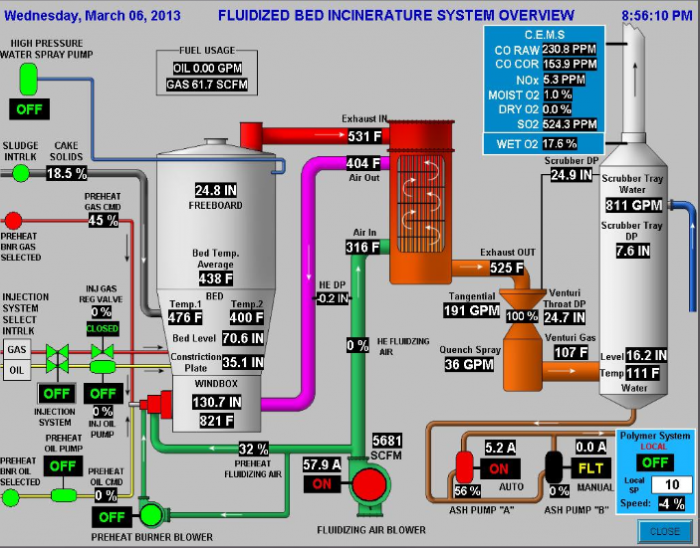

Fluidized Bed Incinerator Instrumentation and Controls

- Fluidized Bed Incinerators can be built, or rebuilt with state-of-the-art control systems. Advanced Process Controls can be used to optimize the system for maximum product yield, product quality, and fuel savings.

- Control packages can be customized to give the customer a fully automated machine, to a basic package that requires manual intervention at every step.

- All systems can be automated.